Reciprocating Friction Tester agencies|slip friction test : manufacturing The High-speed reciprocating friction and wear tester is mainly used for testing the friction and wear performance of materials and surface coatings. The machine uses weight loading 50g-2000g; automatic constant loading; dynamic alternating loading: (sine wave loading, triangle wave, gradient loading) three loading modes, which can simulate . Resultado da AZNude has a global mission to organize celebrity nudity from television and make it universally free, accessible, and usable. We have a free collection of nude celebs and movie sex scenes; which include naked celebs, lesbian, boobs, underwear and butt pics, hot scenes from movies and series, nude .

{plog:ftitle_list}

web26 de ago. de 2022 · Notícias | Grupo de adolescentes espanca menina com socos e puxões de cabelos na saída de escola. TUDO FILMADO. VEJA VÍDEOS | Portal do .

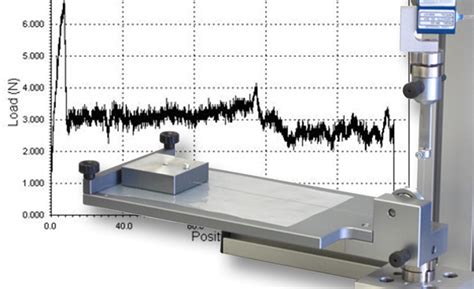

Using various sensors it measures friction, wear, and adhesion of any reciprocating test setup with ease. The patented in-line 3D profilometer automatically measures topography change during the test. The module . A reciprocating sliding friction and wear test rig is a device used to study materials’ wear and friction properties under sliding conditions. It simulates the conditions of real-world applications such as gears, bearings, .The equipment has two forms of motion, so it includes two test modules, which are easy to replace and can meet more test requirements. Rotating module: The equipment moves in a rotating way to achieve a variety of friction contact .The High-speed reciprocating friction and wear tester is mainly used for testing the friction and wear performance of materials and surface coatings. The machine uses weight loading 50g-2000g; automatic constant loading; dynamic alternating loading: (sine wave loading, triangle wave, gradient loading) three loading modes, which can simulate .

MFT-R4000 high speed reciprocating friction wear tester. MFT-R4000 is a multifunction tester used for evaluating the high speed reciprocating friction and wear performance of materials and films under different environment with variation of load, frequency, temperature and gas. It is also applied in the friction and wear measurement under .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of .The machine uses weight loading 50g-2000g; automatic constant loading; dynamic alternating loading: (sine wave loading, triangle wave, gradient loading) three loading modes, which can simulate point, line, and surface contact forms to reciprocate to achieve different test force, friction frequency, friction coefficient and other friction . The initial decrease in friction in the reciprocating tests on 316L stainless steel, reducing ploughing friction through smoothing of surface asperities, was also observed in 10-cycle nano-scratch tests at 30 mN with a 3.7 μm radius diamond [9] (data converted to friction coefficient in Fig. 9) and in 1 N tests on copper with a 100 μm radius .

After-sales Service: 1 Year Warranty: 1 Year Type: Friction Testing Machine Maxcapacity: <1000KN Accuracy Grade: 1 Load Way: Electronic LoadHistorical/Traditional Test Geometry. The classic work of Thurston 1, Martens 2, Stribeck 3 and Hersey 4 were done using a journal-bearing geometry, which possesses all of the above requirements (Figure 3). An instrumented journal-bearing test allows for evaluation of the friction over a range of relative velocities and/or loads. Measurement and control system design and texture anti-friction test of reciprocating friction tester based on compliant mechanism November 2021 DOI: 10.1117/12.2612004Rtec SRV Tester studies friction and wear of lubricants and grease. ASTM, DIN, ISO compliant, with wide test range. Stroke control from 5um . Dedicated SRV tester for reciprocating friction and wear analysis. SRV Test on Multi Function Tribometer MFT-5000. SRV test on the MFT-5000 allows several other friction, tribology, wear tests on the .

Aiming at the reciprocating motion existing in the space rolling bearing, the wear characteristics of the reciprocating friction of MoS2 were studied. The friction simulation between Fe–Ni–Cr substrate and MoS2 is simulated by mixing multiple potential functions. and came to the following conclusions: . such as gas and magnetic suspension . The rig used is a slightly modified version of the one developed for unidirectional sliding by the present authors in Bin Jaber et al. [36].The approach is somewhat similar to the sled-type friction test in ASTM D1894 [37].A schematic representation of the rig is shown in Fig. 2 (with numbers indicating the key components). The contact adopted for the study was a flat . The more usual arrangement is Fig 1 The simple reciprocating friction and wear tester 0301-679X/80/010011"05 .00 1980 IPC Business Press TRIBOLOGY international February 1980 11 Moore and Noah - Friction and wear tester pneumatic loading of the test sample, as shown in Fig 3. Here, a pneumatic load cylinder under the action of air pressure .

The vertical load, friction ball diameter and reciprocating movement frequency (friction speed) are selected as the experiment factors. The cutting tools was installed in the special designed fixture on a reciprocating movement wear test machine. The wear depth increases with the increase in the Z-load, ball diameter and frequency.

slip friction test

In brief, an in-house-built tribometer was used and operated in ball-on-flat linear reciprocating test conditions with a stroke of ~1 mm at a reversing frequency of ~1 Hz. Plane polished titanium alloy (Ti6Al4V) samples were used along with 10 mm diameter counterbodies (hardened 100Cr6 steel or Si 3 N 4 ceramic) in dry or oil-lubricated .To facilitate the in-depth study of the tribological behavior of texture friction pairs in the process of reciprocating friction. The micro-displacement deformation output model of compliant mechanism is deduced using a new method for indirectly measuring friction coefficient through micro-deformation of double parallel four-bar compliant mechanism. Then, the whole structure . 2.1 Pin-on-Disk Tribometer. The most commonly used configuration for testing materials is the pin-on-disk method in either rotating or linear-reciprocating modes. The corresponding ASTM standards, G99 [] and G133 [], include the measurement of friction coefficient as well as wear rate of the sample and the static partner.The pin-on-disk setup has .

1. Maximum test force: 500N 2. Speed range: 1-2000 rpm 3. Frequency range: 1-80Hz 4. Maximum reciprocating friction: 100N 5. Maximum rotating torque: 4.7Nm 6. Reciprocating displacement range: ± 6mm 7. Reciprocating friction forms: ball-disk, pin-disk and pillar tile 8. Rotary friction type: ball-disk, pin-disk and end face 9. Under dry friction, the frequency spectrum analysis of sound pressure at the friction initial stage (a) and stable stage (b) of test samples is shown in Fig. 15. At the friction initial stage (see Fig. 15 a), the dominant frequency of the sound pressure of CM-SACT1, CM-SACT3, CM-SACT5 and CM-SACT7, respectively, are 1396.36 Hz, 216.54 Hz, 221. .Reciprocating Friction Wear Test System | Linear Reciprocating Friction Wear Test System (Model RFW160) is a reciprocate type device that is available to use for the evaluation of wear resistance of the substances such as metal, non-metal, plastic and coating materials. . – Request from a law enforcement agency according to a legal .The analysis of friction and wear properties of materials at elevated temperatures has become increasingly important, especially for the development and quality control of combustion engine and power plant constituent parts.To meet the resulting need for quantitative data at elevated thermal conditions Anton Paar has extended its range of pin-on-disk tribometers with a .

Friction and wear study of sliding surfaces plays a prominent role in the development of materials for various applications. The development of a low-cost multipurpose reciprocating tribometer at constant sliding speed to study the tribological properties of a material under dry, wet and high temperature conditions is presented in this paper. The tribometer has the ability of .MGW-02 high-frequency reciprocating friction and wear testing machine Introduction: The high-frequency reciprocating fatigue friction and wear testing machine can achieve friction and wear performance testing between materials or coatings under small contact pressure, variable frequency range, and reciprocating motion conditions.2.Set the test parameter: Stroke length, reciprocating frequency, friction, test temperature and test time. It also can do the course setting to each parameter. 3.Control the mechanical part running time, it can keep monitoring the stroke length, reciprocating frequency and sample temperature. When the temperature is at the set value, the test . Various types of tribometers are used to assess friction and wear of contacting surfaces viz. pin on disc tribometer, four-ball tester and high frequency reciprocating tribometer. The pin-on-disk tribometer is a laboratory apparatus for evaluating the friction and wear properties of different materials under different conditions of load, speed .

Frequency Friction Machine, running at 15 Hz and 15 mm stroke. The transition from static friction to dynamic friction at the beginning of each stroke and the resulting resonance is apparent in all unfiltered reciprocating tribometer friction force measurements, assuming that the measuring system has sufficient signal bandwidth.Featuring a patented test principle, the SRV®5 tribometer allows for high-precision friction and wear tests of lubricants, materials, coatings and components. The SRV®5 tribometer offers a wide range of practice-relevant test concepts, even in its standard configuration with oscillation.

sliding friction test

linear wear friction testing

linear friction tribometer test

webThe latest tweets from @NordestinaJapa

Reciprocating Friction Tester agencies|slip friction test